Mining Ore Ceramic Dewatering Equipment, Ceramic Vacuum Filter for

Sludge Dewatering

The company has started developing and manufacturing ceramic

filters since the 1990s.It is new, efficient, energy-saving and

environment-friendly high-tech dewatering equipment that integrates

micro-porous ceramics, electromechanical and ultrasonic

technologies and automatic control. It has passed the national

technical appraisal and rated as National Key New Product.

Technical Service

In the spirit of pioneering, innovation and all-round service, we

are dedicated to providing best solutions for filtration and

dewatering of domestic and foreign iron concentrates, copper

concentrates, zinc concentrates, sulfur concentrates, nickel

concentrates, lead concentrates, aluminum concentrates, gold

concentrates, vanadium concentrates, non-metallic concentrates, as

well as beneficiation of low-grade phosphorite, filtration and

dewatering of various tailings, and other technological and

environmental problems.

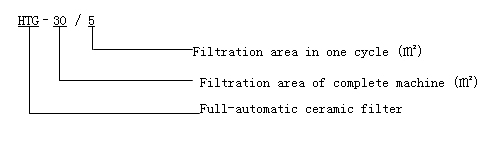

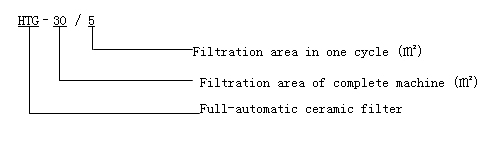

Model Description of Ceramic Filter

Technical Specifications

Model Parameter | HTG01/1 | HTG06/3 | HTG09/3 | HTG12/3 | HTG15/3 | HTG18/3 | HTG21/3 | HTG24/3 | HTG30/3 |

| Filtration area | 1 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 30 |

| Installed power | 6 | 8 | 10 | 11 | 14 | 15 | 15 | 15 | 18 |

| Weight(t) | 2.2 | 5.6 | 7.9 | 8.5 | 9.2 | 9.9 | 10.2 | 11.2 | 12.8 |

| Length (mm) | 1910 | 3062 | 4170 | 4360 | 4770 | 4780 | 5375 | 5453 | 6318 |

| Width(mm) | 1900 | 3025 | 2935 | 3200 | 3200 | 3200 | 3200 | 3200 | 3400 |

| Height (mm) | 1780 | 2750 | 2750 | 2750 | 2750 | 2750 | 2750 | 2750 | 2750 |

Model Parameter | HTG45/3 | HTG51 / 3.75 | HTG45 / 3.75 | HTG60/4 | HTG80/4 | HTG15/5 | HTG20/5 | HTG25/5 | HTG30/5 |

| Filtration area | 45 | 51 | 45 | 60 | 80 | 15 | 20 | 25 | 30 |

| Installed power | 22 | 22 | 22 | 30 | 40 | 17 | 17 | 18 | 20 |

| Weight(t) | 15.6 | 13.1 | 12 | 18.5 | 24 | 7 | 7.2 | 7.9 | 9.5 |

| Length (mm) | 7998 | 6300 | 6100 | 8054 | 9562 | 3930 | 4470 | 4690 | 4810 |

| Width(mm) | 3410 | 3020 | 3020 | 3150 | 3510 | 3410 | 3510 | 3510 | 3510 |

| Height (mm) | 2750 | 2720 | 2720 | 3270 | 3233 | 2980 | 2980 | 2980 | 3035 |

Model Parameter | HTG45 /5 | HTG50 /5 | HTG60 /5 | HTG80 /5 | HTG100 /5 | HTG120 /6 | HTG144 /12 | HTG180 /12 | HTG204 /12 | HTG240 /12 |

| Filtration area | 45 | 50 | 60 | 80 | 100 | 120 | 144 | 180 | 204 | 240 |

| Installed power | 22 | 22 | 29 | 39 | 43 | 57 | 67 | 114 | 116.8 | 121 |

| Weight(t) | 11.3 | 12.5 | 14 | 18.5 | 23 | 25 | 28.5 | 39 | 42 | 45 |

| Length (mm) | 5470 | 5690 | 6130 | 7253 | 8094 | 9437 | 7260 | 9670 | 10470 | 11670 |

| Width(mm) | 3510 | 3510 | 3510 | 3510 | 3510 | 3565 | 5330 | 5330 | 5330 | 5330 |

| Height (mm) | 3035 | 3035 | 3035 | 3035 | 3035 | 3295 | 4786 | 4786 | 4786 | 4786 |

Working Principle

The full-automatic ceramic filter mainly consists of the rotor,

distribution head, agitator, scraper, slurry tank, back flushing

system, ultrasonic cleaning system, PLC operating system and

electric control system.

When the vacuum zone starts working, the ceramic filter plate

immersed in the slurry forms a thick layer of granular stack

rapidly on the surface of the ceramic plate under the action of

vacuum, and the filtrate is filtered through the ceramic plate to

the distribution head to reach the vacuum drum. In the drying zone,

the filter cake continues to be dewatered under the action of

vacuum until dry, and then it is transported by belt to the desired

place after being scraped off in the discharge zone.

After discharging, the ceramic plate finally enters the backwash

zone. The filtered backwash fluid enters the interior of the

ceramic plate through the distribution head and flushes the

particles blocked in the micro-pore of the ceramic plate, thus

completing a cycle of filtering operation. After running for a long

time, the filter can be cleaned by combining the ultrasonic and

chemical media to maintain its efficient operation.

Product features

- Dewatering & drying performance with high vacuum and good filter

cake, high productivity and excellent solids recovery.

- Clear filtrate, neat work environment, and all-directional

environmental protection system without pollution

- PLC program control, high automation, easy operation, and high

utilization of equipment.

- Compact design, high performance, ultra-low operating and

maintenance costs, and remarkable energy saving.

- Ceramic filter plate has a long service life and wide application.